-

+86 138 5974 0886

+86 138 5974 0886 Mr. Zhang

+86 186 8533 4928 Miss Zhang -

- language

+86 138 5974 0886 Mr. Zhang

+86 186 8533 4928 Miss Zhang

Introduction

Introduction

Product categories

Contact us

Five Major Advantages for Your Peace of Mind

Years of industry experience

◇ The company operates a 5,000-square-meter manufacturing facility and possesses over 10 years of experience in precision metal fabrication. It employs 20 engineering and management personnel. ◇ Experienced technical team + dedicated project liaison, ensuring rapid response and quick prototyping to meet diverse industry client needs.10+

10+ years of extensive experience

20+

Professional Team

Own factory, better prices

◇ The company possesses robust technical capabilities, stringent quality control, mature management practices, and a team of skilled professionals, ensuring comprehensive quality assurance for all products. ◇ Direct from manufacturer, supporting customization based on your drawings or samples. Eliminate middlemen for better value and more reliable delivery times.guarantee

Strong technical capabilities

Direct Supply

Customization by Design

Powered by Proven Capabilities

◇ Equipped with 150 high-precision automatic lathes and CNC machines, including CNC lathes, CNC sliding headstock lathes, automatic lathes, turning-milling centers, and related auxiliary processing equipment. ◇ ±0.005mm machining precision, meeting all high-demand custom requirements.150+

High-precision equipment

±0.005mm

Machining accuracy

Reputation Guarantee

◇ Our products are exported to Europe, America, and Southeast Asia, with clients spanning multiple industries including 3C electronics, automotive parts, home appliances, lighting fixtures, hardware, and machinery. ◇ OEM/ODM partnerships welcome. Fast delivery. Free quotes!200+

Partner Clients

100+

Application Areas

Thoughtful after-sales service

◇ Our comprehensive after-sales service ensures a seamless experience from order placement to completion. We listen to your feedback, resolve your issues, and deliver a hassle-free, time-saving, and worry-free service experience. ◇ Rigorous quality control procedures, rapid response to customer needs, and 24/7 customer service are at your disposal. We regularly follow up with both new and existing clients and welcome your suggestions and feedback!Rapid Response

Thoughtful After-Sales Service

7x24h

Customer Service

Focus on product details and emphasize quality

High-precision precision machining

Dixin Precision Hardware achieves extremely high precision, typically with tolerances in the micrometer range and even down to the nanometer level. This ensures components can be accurately assembled with other parts.Smooth surface

Features an exceptionally smooth surface finish to minimize wear, enhance corrosion resistance, and improve aesthetics. The surface roughness value is extremely low.Rugged and durable

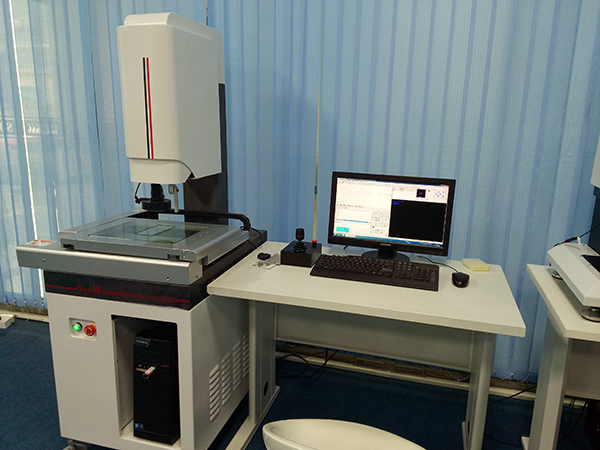

Features high strength, high-temperature resistance, and corrosion resistance. Common materials include stainless steel and various specialty engineering plastics. Video Showcase

Video Showcase

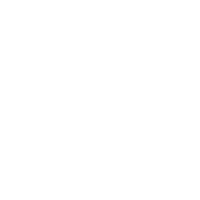

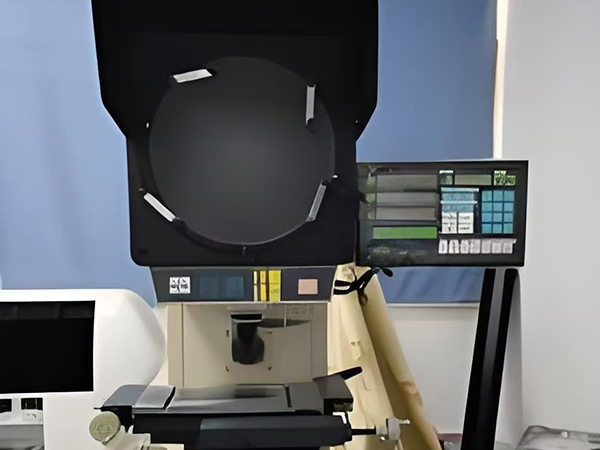

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Video Showcase

Video Showcase

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Video Showcase

Video Showcase

Equipment

Equipment

Video Showcase

Video Showcase

Equipment

Equipment

Production workshop

Production workshop

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production

Production

Company Equipment

Company Equipment

Company Equipment

Company Equipment

The choice of numerous well-known enterprises

Phone

Contact

TOP